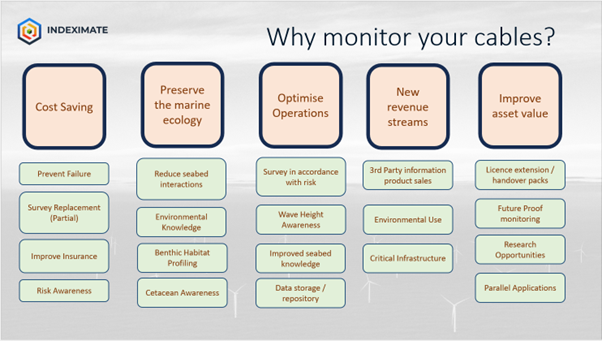

Surely that’s obvious? To prevent failure and save the crippling expense of a repair? Well that’s true, but it’s nowhere near all of the value.

Clearly, not having to spend £20m on a repair and wait 6 months to do it is a good thing… But the savings don’t stop there and it’s not JUST a risk play. The act of monitoring your cables can do much more for your cost position:

- Improve your insurance position – most insurers are pro monitoring (and if your’s isn’t take our certificates to a broker who will make sure they are) and commitment to both health check monitoring and continuous monitoring will improve your insurance position – it has the ability to reduce your deductible, improve your coverage and also your premium. Put simply, it allows insurance to return to being a transfer of risk of unpredictible events – i.e. the predictible is now managed and dealt with by preventative maintenance.

- Reduce your survey costs – you know the drill – running up and down the cable in a linear manner, once every few years, in an windfarm covering 1/4 of your footprint every year. It’s informative but inefficient. Cable monitoring allows you to run shorter more targeted surveys each year covering the whole windfarm by knowing where to look

Sticking with the money theme, it also has the potentil to overall improve your asset value. Considering the end of licence or the handover period to a TSO/OFTO. A robust cable survey can take previously unanswerable questions off the table and improve the book value of the asset. Knowing your cable is in great condition is a tremendous comfort blanket to a new owner. The presence of condition monitoring and a history of Indeximated data can future proof your monitoring requirements (when a new analysis arises it can immediately be applied to years of historic data), can lead to research opportunity with 3rd parties for forensic analysis and the data itself has a value that can be liberated – so let’s talk about new revenue streams.

Unique to the Indeximate approach is that we port your DAS data to the cloud (“what, no, it can’t be done ” etc etc). We hear this time and time again that the main blocker to exploiting fibre sensing – well we don’t accept that. We will store a year or more of data and what’s more we’ll enjoy doing it. Cable change mechanisms take place over long periods of time so you NEED to be able to store and handle long data streams. Our Indeximation approach does exactly this – it creates an interrogable indefintiely long data series in the cloud. Once there we can create alternative information products for 3rd parties – think of wave height data for operations for example. There’s a long list of potential applications and these have a value that can be realised. Work with Indeximate to liberate this value and earn a return from your condition monitoring!

Sticking with that topic of wave height – this and other data has a huge benefit to allowing you to optimise your operations. You are considering an intervention and are relying on METOC data to understand wave height conditions -instead of gross averages we can liberate the wave height at all points along your cable (which means around your windfarm) at all times with pinpoint precision. This and other seabed data & environmental data allows you to optimise your operations.

Finally, environmental impact is not talked about enough. Our industry addresses it carefully in planning stages and there will be some monitoring through life. But hold on, we are collecting a wealth of data about the interaction of the cable with the environment and most of it gets thrown away! This is crazy – in the interest of digital twinning and more complete profiling,cable condition monitoring becomes our key sensor in the middle of the environment we are working in – let’s use it. Knowledge of cable seabed interaction over time? Seabed temperature change? Cetacean monitoring? Benthic profiling? All are possible direct products or researhc products that can be delivered. Again let’s go back to Indeximation – we’ve created a massive store of data about your windfarm or cable – this can be put to work for environmental monitoring purposes with research insitutions or in-house operations.

So there is a wealth of potential uses – monitoring is not JUST about cable condition and failure prevention although clearly that’s the main motiviation. Let’s expand the conversation from there and explore what else can be achieved. Listen to what your cables are telling you!